Measurements of spray induced cooling

Measurements of spray induced cooling

Person in Charge: Dr. Aldo Mendieta

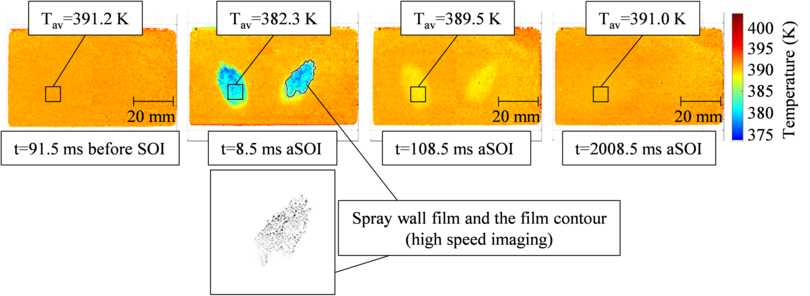

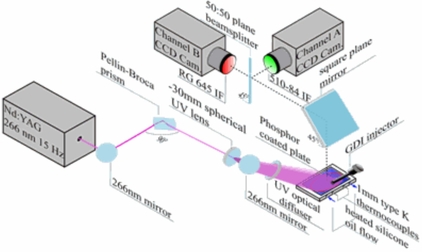

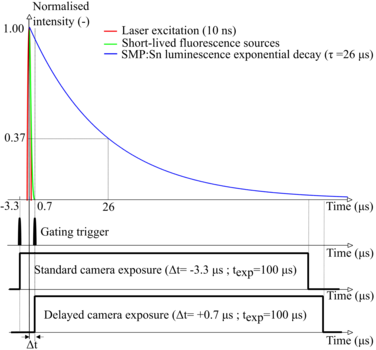

Recent trends towards reducing particulate emissions in Gasoline direct injection - GDI engines focuses on fuel film formation in wetted, sprayed surfaces. The incomplete evaporation of those films, prior to combustion, is a main precursor for soot formation. A precise knowledge of the instantaneous wall temperature during and after film deposition is a key factor for adopting preventive injection strategy measures. Recent improvements in Phosphor thermometry allows for contact-less, fast, interference-free temperature measurements from the wetted face of impinged walls with integration times in the range of microseconds. Even when using real, fluorescent fuels uncertainties below 1 K are possible.Phosphor thermometry exploit temperature induced changes in the photoluminescence behavior (typically the lifetime variation or the emission spectrum shift) of phosphor materials. These materials, normally available in powder form with micrometer sized particles, are coated onto the surface of interest for temperature interrogation.

At LTT, we developed different measurement strategies to further maximize the phosphor's measurement capabilities for this range of applications, such as delayed camera gating. We also introduced semi-automated surface coating techniques to obtain very thin, homogeneous and strongly luminescent phosphor coatings.

|

|