Carbon dioxide separation from exhaust gases

Person in charge: Alexey Kropman

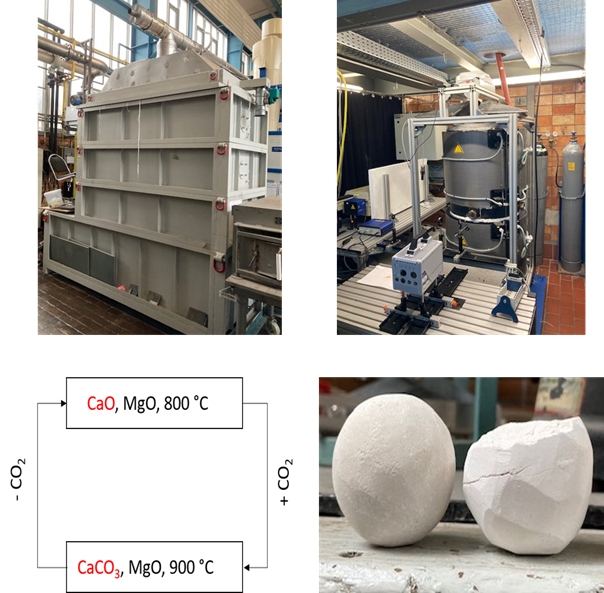

In this project we are developing a new process for energy efficient CO2 separation from industrial exhaust gases. The basis is the well-known calcium looping process where CO2 reacts with CaO to form CaO3 which is later decomposed to CaO and CO2 again. At the end, we achieve clean CO2 ready for utilization or sequestration. In contrast to the usual implementations in a fluidized bed, our process is performed in a packed bed. The extraordinary complexity of the underlying sub-processes gives rise to various experimental research topics.We study the overall process in a semi-industrial shaft kiln, do realistic one-particle measurements in a smaller tube kiln and study the long-term cyclic behavior of the target-material in small-sized TGA and DSC experiments. Besides classical IR-based temperature measurements we also apply the innovative technique of phosphor thermometry using laser light. The experimental part is accompanied by process modeling and economical calculations regarding different process strategies.